yuz wan barkɔd manejmɛnt sistem fɔ .:

Otomatik verify di matirial yuz fɔ mek dɛn nɔ yuz am di rɔŋ we.

Archive batch infɔmeshɔn in rial tɛm, traceable to raw matirial sɔs, yuz tɛm, ɛn kɔrɛspɔndɛns prodakshɔn wok dɛn.

Select Language

Select Language

I. Prodakshɔn kapabiliti dɛn .

As di teknikol kor ɛn kwaliti ɔrijin fɔ di kɔmni, di kɔmpawnd miksin wokshɔp spɛshal pan pɔshɔnal miks rɔba prodakshɔn. I gɛt di industri-lida prodakshɔn layn dɛn ɛn di intɛligent batch sistem dɛn, i de mek wan prodakshɔn sistem we de kɔba ɔl di kayn rɔba dɛn:

– 4 Ful ɔtomatik rɔba miksin prodakshɔn layn dɛn .

– 4 Preforming Ikwipmɛnt Yunit dɛn .

– Annual prodakshɔn kapasiti we pas 10,000 tan

Dis advans hadwae konfigyushɔn de mek shɔ se efishɔnal ɛn stebul delivri fɔ multi-kategori miks rɔba prodak, mit kɔstɔmayz nid fɔ difrɛn klayɛnt dɛn.

II. Kor ekwipment .

(1) Intɛligent batch sistɛm .

Wan ful ɔtomatik matirial manejmɛnt sistem de mek dijital kɔntrol fɔ prodakshɔn wok dɛn .:

Intɛligent batch .:Risipi paramita dɛn de input insay di sistem, we ɔtomɛtik wan wej ɛn prɔpɔshɔn matirial, we de pul mɔtalman mistek.

Dynamic Monitoring .:Rial-taym wet dɛvyayshɔn alarm dɛn kin trig ɔtomɛtik we batch wet pas sɛt trɛshɔld, mek shɔ se ɔl di matirial dɛn pas standad verifyeshɔn bifo dɛn go bifo to di nɛks prɔses.

Proses Traceability .:Ful-proses dijital rɛkɔd dɛn de mek dɛn ebul fɔ gɛt prɛsis kɔrɛleshɔn bitwin rɛsipɛkt ɛn matirial dɛn.

(1) Preforming Processing Ikwipmɛnt .

Kɔmpozishɔn: 2 Kol-fid prɛsishɔn ɛkstruda dɛn + 2 hot-fid prɛfɔmin mashin dɛn

Teknik brek-bruk: Riples tradishonal manual kot en weigh.

Di bɛnifit dɛn we pɔsin kin gɛt we i de wok fayn fayn wan .:

weit tolerans we dɛn kin kɔntrol insay . ±0.2g

Vulcanization prodakshɔn efyushɔn bin go ɔp bay . 40%

Rɔba matirial yutilizeshɔn impɔtant bay . 10%

III. Kwaliti Kɔntrol Sistɛm .

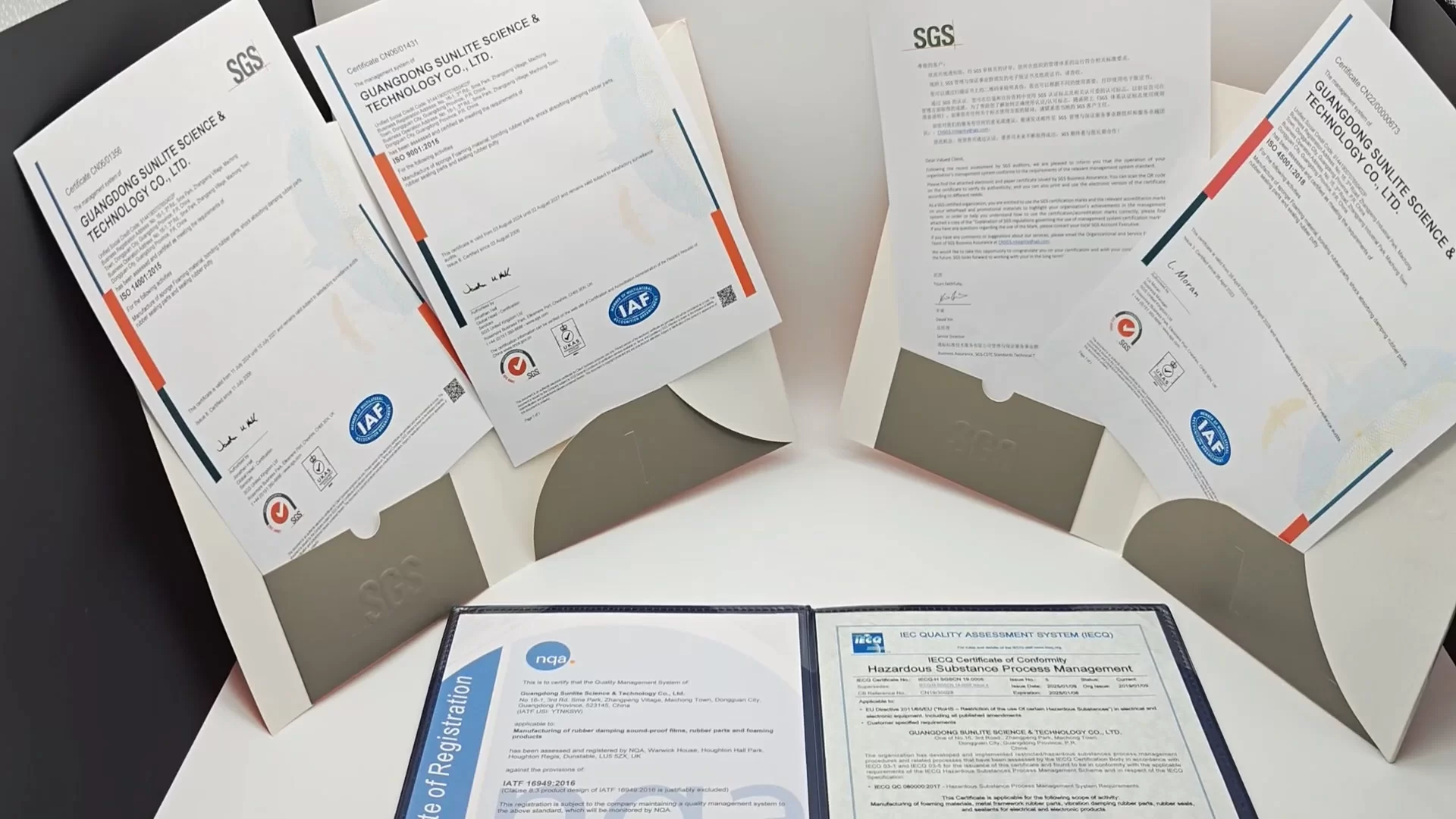

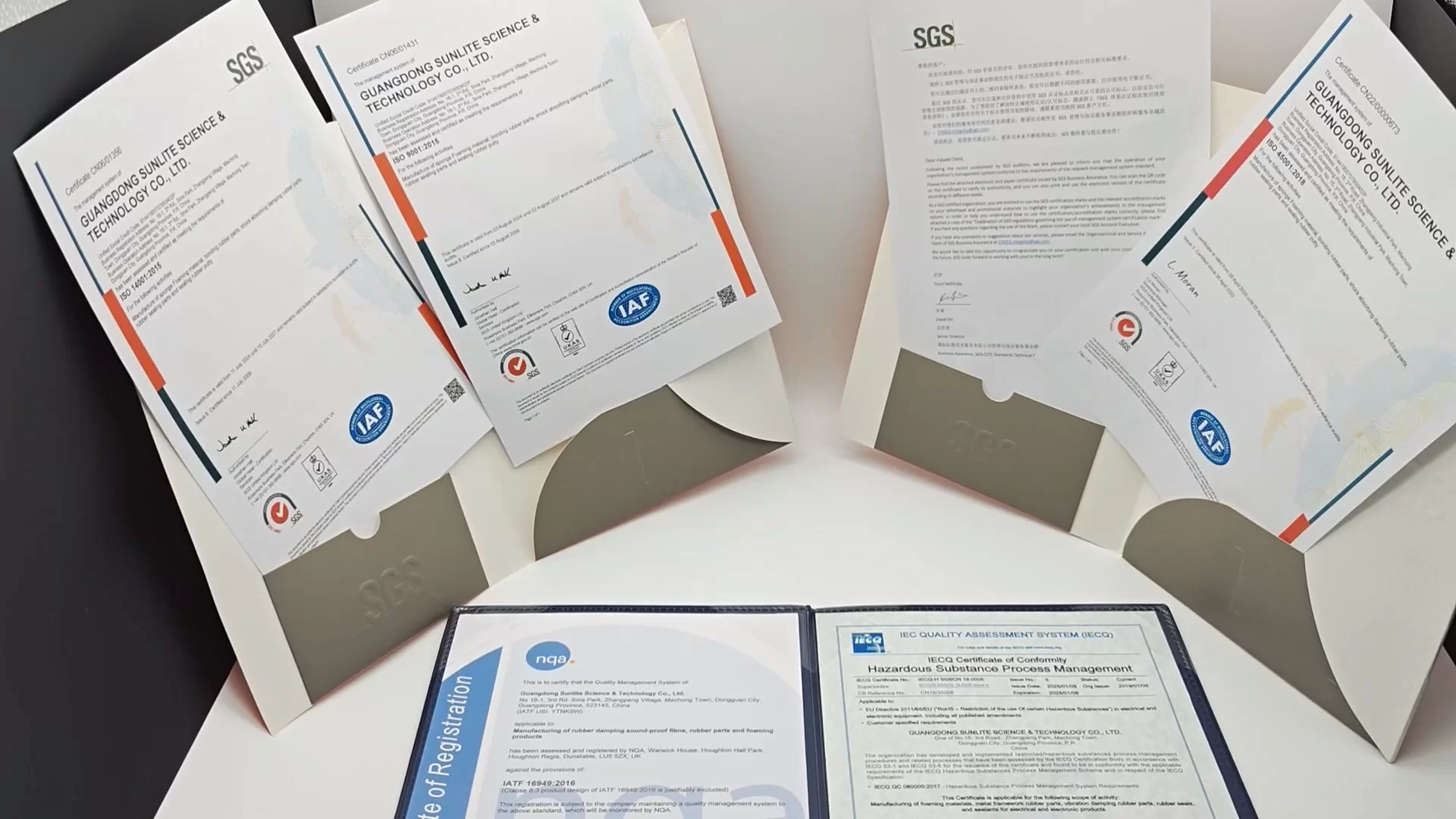

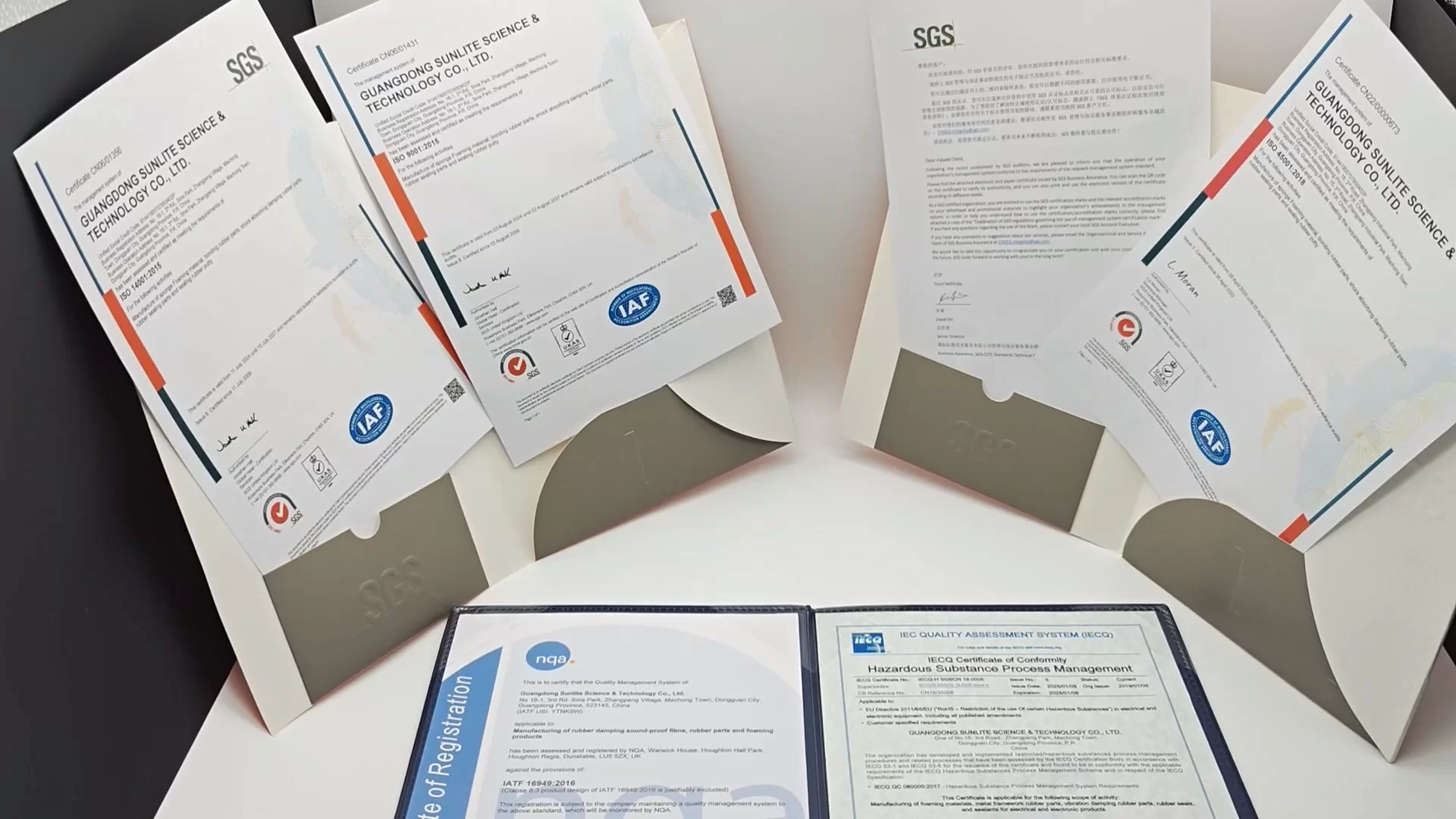

Manejmɛnt Sistɛm Sɛtifikeshɔn dɛn .

Wan ful-prɔses kwaliti kɔntrol fɔm we dɛn bil tru intanashɔnal ɔtoriti sɛtifiket dɛn .

ISO 9001 Kwaliti Manejmɛnt Sistɛm .

ISO 45001 Ɔkupeshɔn Ɛlth ɛn Sefty Manejmɛnt Sistɛm .

ISO 14001 Envayrɔmɛnt Manejmɛnt Sistɛm .

IATF 16949 Ɔtomotiv kwaliti manejmɛnt sistem .

Di Ikwipmɛnt fɔ Kɔntrol Prɔses .

Metal Fɔrin Ɔbjɛkt Ditekshɔn .: Onlayn mɛtal ditektɔ dɛn de monitɔr insay rial tɛm, ɔtomatikal alarming ɛn pul mɛtal impurities.

Multi-stej filtreshɔn sistem .: Yuz 80-mesh, 100-mesh, ɛn 120-mesh filta fɔ gred filtreshɔn bays pan rɔba tayp, we de mek shɔ se nɔ impyuriti rɛsɛdyu.

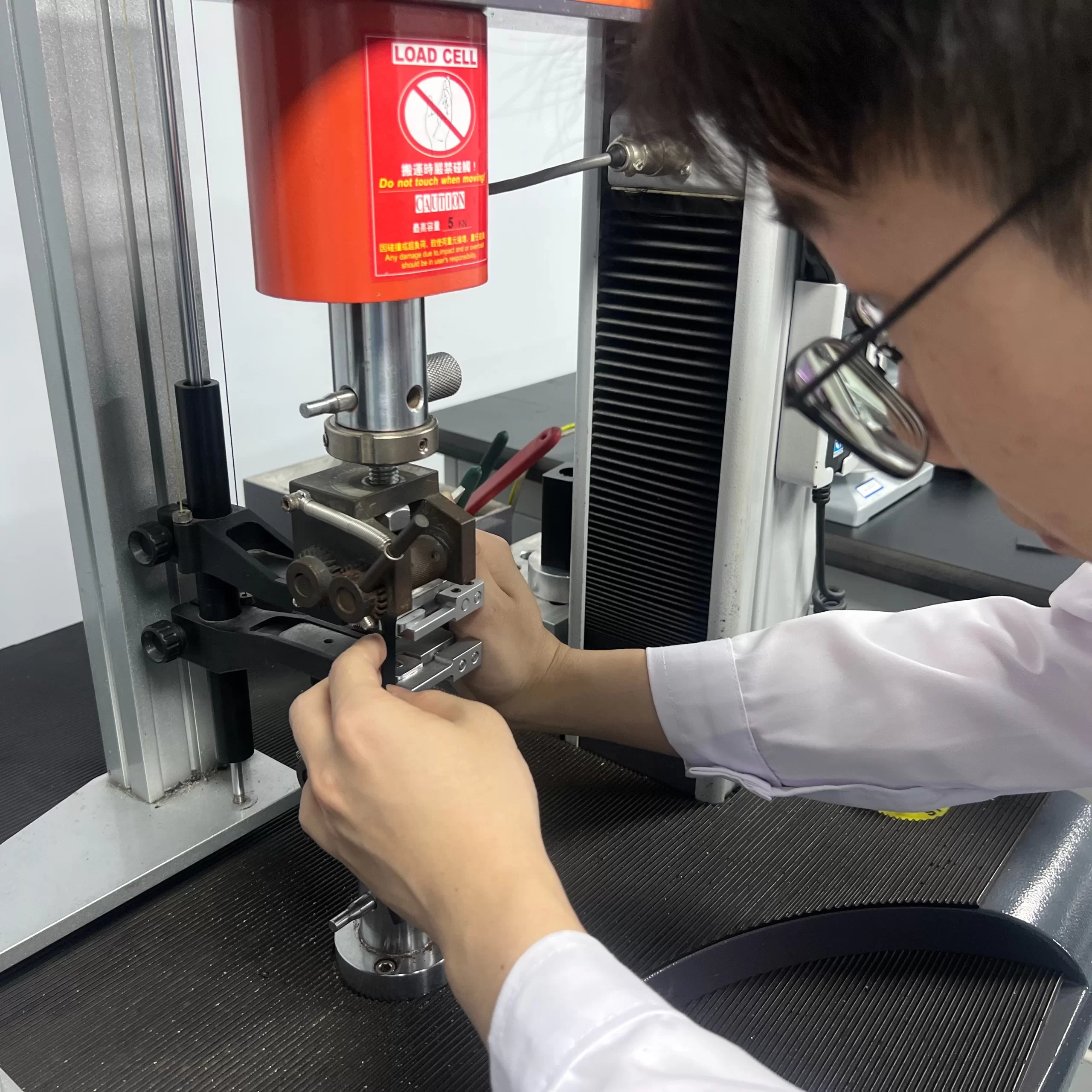

Labɔrɔtɔri tɛst kapabiliti dɛn .

Ikwip wit wan CNAS nashɔnal-lɛvel laboratori

Di tin dɛn we dɛn kin tɛst na:Vulcanization Characteristics (Rheological Testing)

Mooney viskositi .

Fizik ɛn Mɛkanikal Prɔpati dɛn .

Ful-batch tayp tɛst de impruv fɔ mek shɔ se ɛni batch mit tɛnki spɛsifikɛshɔn dɛn.

IV. Ful-prosɛs trasabiliti sistem .

1. Raw Material Traceability .

yuz wan barkɔd manejmɛnt sistem fɔ .:

Otomatik verify di matirial yuz fɔ mek dɛn nɔ yuz am di rɔŋ we.

Archive batch infɔmeshɔn in rial tɛm, traceable to raw matirial sɔs, yuz tɛm, ɛn kɔrɛspɔndɛns prodakshɔn wok dɛn.

2.Prodakshɔn Prɔses Trasabiliti .

Prodakshɔn wok dɛn de kɔmɔt ful dijital wan, wit di sistem we de rikodɔ ɔtomɛtik wan .:

Prodakshɔn Tɛm ɛn Ikwipmɛnt Infɔmeshɔn .

Batching ditel ɛn prɔses paramita dɛn .

Batch autput ɛn prɔses kɔntrol data .

3.Kwaliti Inspekshɔn Trasabiliti .

Ilɛktronik manejmɛnt fɔ inspekshɔn rɛkɔd dɛn .

Sampul Ritɛnshɔn Spɛsifikeshɔn dɛn .:

Mak wit yunik prodak kod dɛn .

Di de dɛn we dɛn dɔn rɛkɔd ɛn inspekshɔn de

Komplit kwaliti arkiv dɛn we dɛn dɔn establish fɔ ful layfsaykl traceability

Tru di tripl garanti fɔ di ikwipmɛnt intɛlijɛns, sistamɛtik manejmɛnt, ɛn dijital traysabiliti, di kɔmpawnd miksin wokshɔp de mentɛn di industri-lida prɔses kɔntrol kapabiliti, deliv ay-kwaliti, rilibul miks rɔba prodak ɛn savis to klayɛnt dɛn.